Short Description:

A concise B2B comparison of polyester cotton (PC) vintage lace versus standard guipure lace, evaluating production cost, stability, raw material supply, and factory-line adaptability to determine which trim better supports consistent custom branding at scale and in varied application scenarios.

Table of Contents

What are they and how do the core techniques differ?

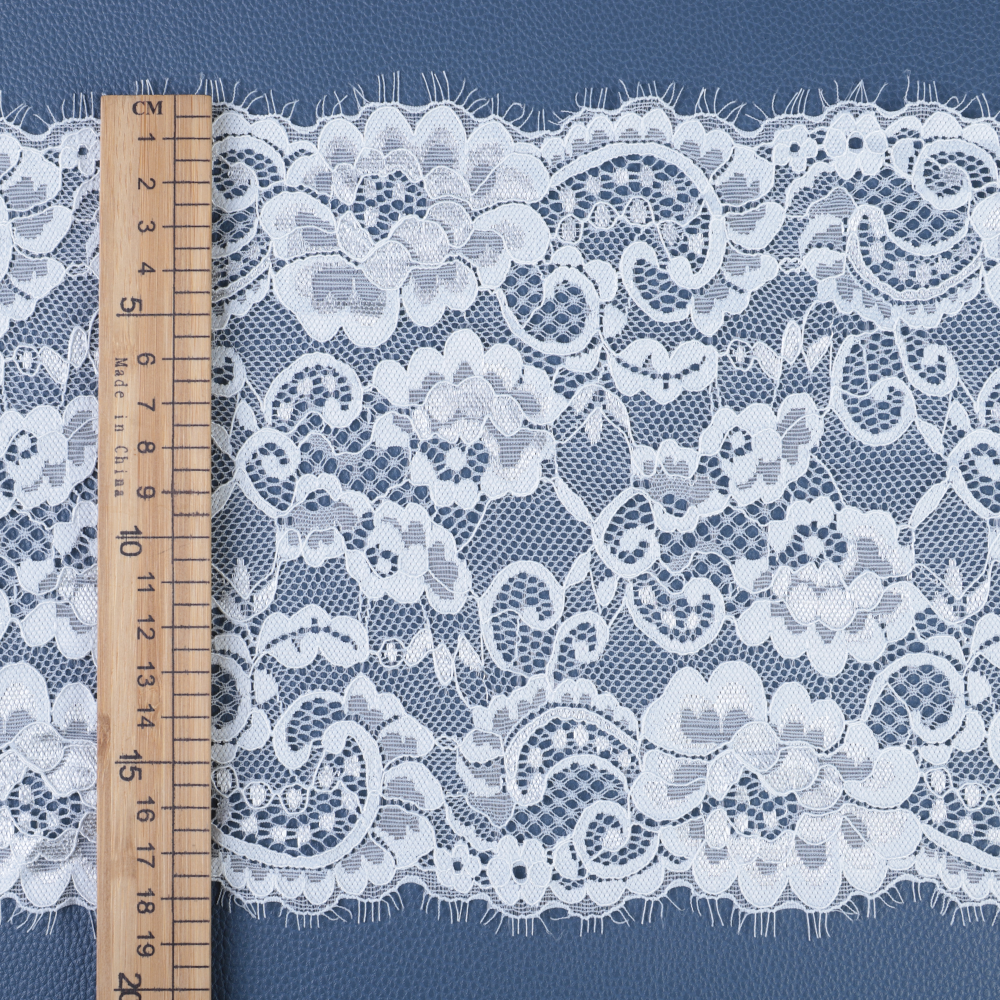

Polyester cotton vintage lace typically uses a poly/cotton blend yarn on narrow looms or embroidery-on-base techniques to achieve a heritage look. The fabric-backed or tape-style construction gives it body, easy sewability, and reliable edge control—favorable for repeating brand borders or logo-integrated tapes.

Standard guipure lace (a.k.a. chemical lace) is created by embroidering motifs densely on a water-soluble base, then washing the base away to leave free-standing designs connected by bars. It delivers high-relief motifs and premium visual impact, but without a backing it demands more precise handling during sewing and finishing.

What is the difference between embroidery and screen printing?

Embroidery uses threads to stitch designs onto fabric, offering a raised, textured finish. Screen printing applies ink through stencils, producing flat, colorful prints. Embroidery is ideal for smaller, durable designs, while screen printing suits larger, intricate patterns.(Embroidery vs Screen Printing: Which is Best for Your Needs?)

How do production costs compare for custom programs?

PC vintage lace benefits from commodity blend yarns, efficient loom/embroidery throughput, and simpler finishing; adding custom colors or repeating wordmarks via jacquard or digitized embroidery is cost-predictable once artwork is approved. Per-meter costs scale well with volume, making it suitable for multi-style branding programs.

Guipure lace consumes more thread, higher stitch densities, and soluble-base materials, plus extra washing and drying steps. Custom shapes or branded crests require re-digitizing and sampling, and yield loss can rise on intricate edges. While standard motifs can run economically, bespoke branding typically prices higher than PC vintage lace.

Is screen printing cheaper than embroidery?

Screen printing is generally more cost-effective for large orders due to lower per-unit costs at higher volumes. Embroidery, with its consistent per-unit pricing, is often better suited for smaller batches.(Embroidery vs screen printing: What you need to know)

Which offers better stability and quality consistency at scale?

PC vintage lace’s fabric-backed or tape construction delivers dimensional stability, seam integrity, and predictable shrinkage (poly moderates cotton’s movement). Color matching across seasons is straightforward with PC dyeing, helping maintain consistent brand palettes across styles and factories.

Guipure’s free-standing structure showcases crisp motif edges, yet bar connections can distort under tension, and edges may snag in bulk handling. Polyester threads provide solid colorfastness, but consistent drape and motif geometry require careful process control—raising QC attention for repeatable branding outcomes.

Which lasts longer: screen printing or embroidery?

Embroidery tends to last longer due to its stitched design, which withstands wear and washing better than screen-printed designs that may fade or crack over time.(Embroidery vs Screen Printing: Which Should You Go With?)

How do raw material supply and risk profiles differ?

Poly/cotton yarns, base fabrics, and standard embroidery threads are widely available globally, with abundant dyehouse capacity and short lead times. This broad base supports rapid replenishment of brand colors and repeat trims, lowering procurement risk for multi-region B2B programs.

Guipure inputs—high-tenacity polyester embroidery threads and water-soluble films—are also widely available, but the soluble substrate and post-wash process add dependency on compliant wet-processing and consistent utilities. Environmental controls and regional wastewater regulations can extend lead times or constrain sourcing options.

What materials are needed for embroidery and screen printing?

Embroidery requires threads, needles, and stabilizers, while screen printing needs inks, screens, and squeegees. The choice of materials affects the cost and quality of the final product.(Difference Between Screen Printing and Embroidery)

How do factory lines adapt to each technique for custom branding?

PC vintage lace arrives as stable tapes or trims that feed cleanly into automated sewing lines, folders, and binding attachments. Artwork changeovers for repeated logos or patterns are digital and fast, supporting synchronized launches across OEM partners with minimal takt-time penalties.

Guipure lace requires gentler handling, slower feed speeds on delicate motifs, and additional in-line inspection to avoid stretch or breakage at connectors. Heat-setting and precise cutting add steps, and trim-to-trim variance can challenge standardized attachments, impacting throughput in high-volume branding programs.

How do factories handle custom embroidery and screen printing?

Factories use specialized machines for each method: embroidery machines for stitching designs and screen printing presses for applying ink through screens. Each has unique setup and production processes tailored to the design and order size.(Understanding The Differences Between Embroidery And Screen Printing)

Application scenarios: Where does each trim excel for consistent custom branding?

Choose PC vintage lace for brand-repeating borders, signature color tapes, kidswear and casualwear trims, home-textile edge branding, and uniform programs where color continuity, cost control, and repeatability matter. It’s ideal for multi-SKU, multi-season ODM/OEM portfolios seeking consistent brand identity across categories.

Choose guipure lace for premium capsules, bridal and occasionwear labels, statement collars/cuffs, or limited runs where brand crests or monograms serve as focal motifs. It elevates perceived value and storytelling but is best applied to curated SKUs rather than high-churn, high-volume branding platforms.

When should I choose embroidery over screen printing?

Choose embroidery for a professional, durable finish on items like uniforms and corporate apparel. Opt for screen printing when producing large quantities of casual wear with vibrant, detailed designs.(Screen Printing vs. Embroidery: What Are the Differences?)

Conclusion

For consistent custom branding in B2B across high-volume, multi-factory pipelines, polyester cotton vintage lace is generally the more reliable, cost-effective, and workflow-friendly option. Standard guipure lace is powerful for premium differentiation and hero pieces but fits best as a complement to, not a replacement for, scalable brand-standard trims.

John Gan

John Gan specializes in professional lace and fabric customization, leading Shaoxing Yituo to expand globally with quality and innovation. He is committed to making the company a leading supplier through strong international partnerships.