Short Description:

This B2B-focused comparison guides buyers and manufacturers through the key differences of black lace and traditional lace, evaluating production costs, material stability, raw material supply, and factory adaptability to determine the best option for mass procurement and sales.

Table of Contents

What are black lace and traditional lace?

Black lace is typically crafted with dyed threads—often using polyester, nylon, or cotton—offering a bold, modern, and elegant appearance. Traditional lace generally refers to white, ivory, or pastel-colored lace, often associated with classic elegance or ceremonial wear, and may be produced with similar base materials. While both can feature similar patterns and structures, color impacts their visual symbolism and market appeal.

What is traditional lace?

Lace fabric was originally made from silk and linen, but today cotton thread and synthetic fibers are both used. Lace is a decorative fabric used to accent and embellish clothing and home decor items. Lace is traditionally considered a luxury textile, as it takes a lot of time and expertise to make.

What is black lace used for?

Black lace can be used to great effect to make a glamorous bridal gown or for evening wear. Either on a dark fabric or a light fabric background, from alternative bridal gowns to evening wear and prom.

How do production costs compare for black lace and traditional lace?

Black lace production may require additional dyeing steps or specialized black threads, slightly increasing per-unit costs compared to undyed traditional (white/natural) lace.

Traditional lace, especially unbleached or undyed, may have lower material and process costs.

For both types, costs depend strongly on design complexity, thread material, and finishing techniques, but traditional lace often has a slight advantage in large-scale standard products.

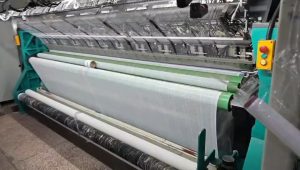

What is lace production?

Lacemaking is the craft of creating openwork fabric patterns primarily using threads, which can be produced through various techniques such as knitting, crocheting, tatting, and weaving.

Which lace offers greater stability and quality consistency in bulk production?

Both black and traditional lace can achieve stable, uniform quality with modern machinery.

Dark dyes in black lace increase the need for careful washing and colorfastness testing—some risk of dye migration or inconsistency may require stricter quality checks on black lace.

Traditional lace, particularly in lighter shades, tends to be more forgiving in maintaining color consistency and minimizes visible production flaws, which can benefit high-volume consistency standards.

What is high quality lace made of?

Traditionally, lace usually consisted of silk or linen threads, and some textile artisans even made this fabric using gold or silver thread. In contemporary times, however, cotton has become the most popular fabric for lace production, and some manufacturers use synthetic fibers like polyester or rayon to make lace.

How do raw material sourcing and supply reliability differ between black and traditional lace?

Both laces are commonly made from widely available fibers (polyester, nylon, cotton), ensuring good supply chain support.

However, sourcing high-quality, deeply colorfast black dye or pre-colored yarn may introduce additional lead times or rely on specialty suppliers, which can increase procurement risk for black lace in some regions.

Traditional lace benefits from a mature and well-established material supply chain, favoring uninterrupted mass production.

Is lace made sustainable?

Handmade lace has minimal environmental impact but is labor-intensive. Machine-made lace is more efficient but relies on synthetic fibers and energy, increasing its carbon footprint..

How adaptable are black lace and traditional lace to automated factory production lines?

Traditional lace in standard colors is highly compatible with automated lace-making lines and large-scale processes, requiring minimal production adjustment.

Black lace can also be automated, but factories may need to adapt rinse, drying, and quality control steps to manage dark dye residues and prevent cross-contamination—potentially slowing throughput or increasing operational oversight.

For plants running a wide color range, transitioning between black and light laces requires diligent cleaning to prevent color contamination.

What is the difference between handmade and machine made lace?

Handmade needle lace displays distinct stitches made by human hands, observable under magnification. In comparison, machine lace, produced by numerous needles working simultaneously, results in less clarity of individual stitches.

Which lace is better suited for large-scale purchasing and sales in the B2B market?

Traditional lace is generally the safer choice for B2B mass purchasing, owing to lower costs, simpler logistics, proven supply reliability, and ease of standardization on automated lines.

Black lace has strong appeal in fashion-forward, seasonal, or high-impact product categories, but may entail slightly higher operational complexity and material oversight.

For B2B buyers prioritizing speed, consistency, and streamlined production, traditional lace is typically more advantageous. However, for differentiated, contemporary collections targeting niche or designer markets, black lace adds value and market distinction if supply chain and factory processes can accommodate its needs.

What is the lace process in sales?

Just like LAARC, LACE starts with Listening and Acknowledging. LACE suggests, however, that you do a trial close after you have understood and acknowledged an objection. Get a commitment from your prospect to purchase if you resolve the objection.