Short Description:

A B2B-focused comparison of vintage crochet lace and fancy embroidered lace trim from production cost, stability, raw material supply, and factory-line adaptability to application scenarios—helping ODM teams choose the right craft for customizable, scalable programs.

Table of Contents

What are the craftsmanship basics and how do they shape ODM customization potential?

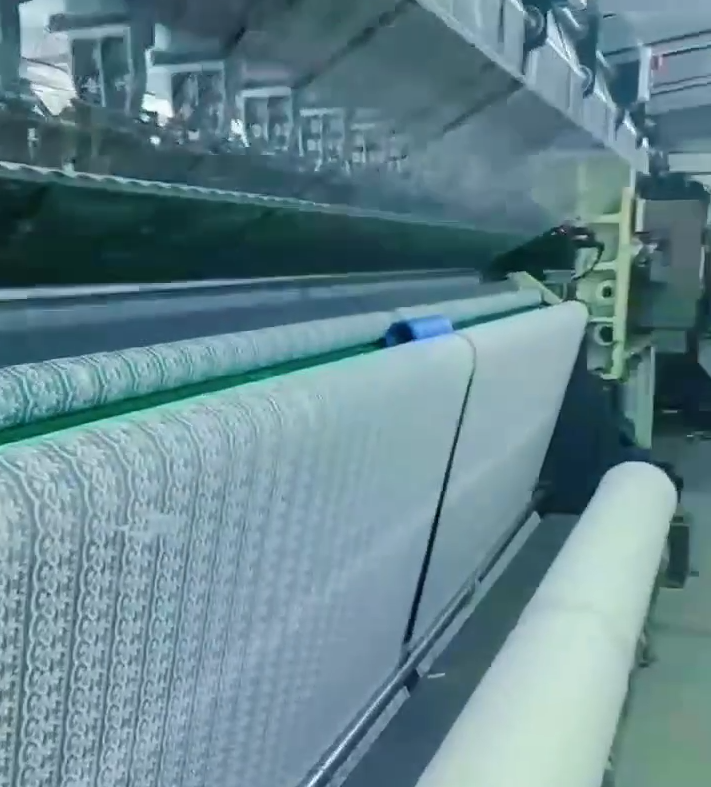

- Vintage crochet lace is built loop-by-loop with cotton or blended yarns, often by hand or on semi-automated crochet machines, yielding artisanal textures and openwork patterns. Fancy embroidered lace trim is produced on multi-head embroidery machines, stitching motifs onto tulle/organza or water-soluble bases, with options for sequins, beads, and metallic threads.

- For ODM customization, crochet excels at heritage/boho aesthetics and tactile depth, while embroidery offers rapid motif iterations via digitized files, richer colorways, and scalable embellishment libraries—ideal for faster design turnover.

How does the intricacy of lace patterns affect customization in ODM manufacturing?

The complexity of lace patterns directly influences customization potential in Original Design Manufacturing (ODM). Intricate designs require advanced craftsmanship and precise execution, which can enhance product uniqueness but may also increase production time and costs.

How do production costs compare, and what does that mean for MOQ and price tiers?

- Crochet’s unit economics are driven by labor time, stitch density, and yarn grade, leading to higher costs and longer lead times per meter; complex borders amplify cost. Embroidered trims leverage automation; primary drivers are machine time, thread/base materials, and embellishments, with one-time digitizing amortized across volume.

- As MOQs rise, embroidery’s per-unit cost decreases predictably, supporting value and mid-tier price points at scale. Crochet is better positioned as a premium upcharge or limited capsule due to higher cost bases and slower throughput.

How do production methods impact the cost of lace fabric?

Handmade lace is labor-intensive and typically more expensive, while machine-made lace offers cost efficiency, affecting Minimum Order Quantities (MOQs) and pricing structures. (modaknits.com )

Which technique delivers better stability and quality consistency for customized runs?

- Embroidered trims deliver consistent width, repeat, and hand feel under machine-controlled tension, aiding colorfastness and wash performance across batches. QC is standardized (needle, thread, stitch density, soluble-base rinse parameters), making repeat orders reliable.

- Crochet’s hand or semi-hand nature introduces variance in tension and dimension; blocking and pre-wash mitigate, but tolerance windows must be defined. It suits SKUs where small artisanal variation is acceptable or desired.

What factors influence the quality consistency of lace in mass production?

Machine-made lace provides better stability and consistency due to standardized processes, whereas handmade lace may exhibit variations, impacting quality in large-scale production. (geekmode.blog )

How do raw material supply chains differ and what risks matter to ODM programs?

- Crochet typically uses cotton or cotton-blend yarns; supply is broad but sensitive to fiber price swings and dye-lot matching. Specialty yarns (mercerized, organic, GRS blends) add value but may extend lead times.

- Embroidery relies on abundant polyester/rayon threads, standard tulle/organza, and widely available water-soluble films; add-ons like sequins and beads come from mature accessory ecosystems. Overall risk is lower and replenishment faster for embroidery components.

What challenges exist in sourcing materials for lace production?

Sourcing high-quality materials like silk and cotton can be challenging due to price volatility and availability, posing risks to ODM programs reliant on consistent supply chains. (pmarketresearch.com )

How well do factory lines adapt to each technique for sampling and mass production?

- Embroidery integrates seamlessly with multi-head machines, CAD digitizing, fast sampling, and streamlined changeovers; lines can scale with parallel heads and standardized QA, supporting frequent ODM revisions and colorways.

- Crochet requires skilled operators or specialized machines with slower cycles; integration into high-speed lines is harder, and capacity scaling depends on trained labor and additional finishing (blocking, trimming), impacting takt time.

How does automation impact lace production efficiency?

Automation in lace-making enhances efficiency and consistency, making factory lines more adaptable to mass production demands.

Application scenarios and B2B recommendations for scalable, customized portfolios

- Use vintage crochet lace for premium capsules—bridal/boho dresses, heritage blouses, artisanal childrenswear, and limited-edition accessories where tactile hand and story justify higher ASPs and smaller MOQs. Position as hero trims or focal borders.

- Choose fancy embroidered lace trim for fast-fashion dresses, lingerie accents, kidswear, uniforms, and home textiles requiring consistent specs, quick repeats, and multiple colorways. It aligns with high-volume OEM orders, tight calendars, and broad price ladders.

What are the advantages of using machine-made lace in large-scale garment manufacturing?

Machine-made lace offers cost-effectiveness and uniformity, making it suitable for large-scale garment manufacturing and scalable B2B portfolios.

John Gan

John Gan specializes in professional lace and fabric customization, leading Shaoxing Yituo to expand globally with quality and innovation. He is committed to making the company a leading supplier through strong international partnerships.