Short Description:

A B2B-focused comparison of cotton crochet lace and cotton eyelet ribbon, analyzing production costs, material stability, raw material supply, and factory line adaptability to identify the ideal lace for large-scale OEM garment manufacturing and application scenarios.

Table of Contents

What are cotton crochet lace and cotton eyelet ribbon?

Cotton Crochet Lace:

Cotton Eyelet Ribbon:

- Features embroidered or woven holes (eyelets) forming a pattern, typically on a narrow cotton ribbon base.

- Known for structured appearance and breathability, widely used in children’s wear, casual apparel, and utilitarian designs.

What is the difference between crochet lace and eyelet lace?

Crochet lace is created by interlocking loops of thread using a crochet hook, resulting in a textured, openwork fabric. Eyelet lace, also known as broderie anglaise, involves fabric with cut-out patterns that are embroidered around the edges, creating a delicate, perforated design.

What are the common uses of cotton crochet lace and eyelet ribbon?

Both are used in garment embellishments, home décor, and crafts. Crochet lace adds a vintage touch to clothing and accessories, while eyelet ribbon is often used for decorative trims on dresses, curtains, and linens.

For more information on crochet lace, you can visit RibbonBazaar’s Cotton Crochet Lace page .

How do the production costs of cotton crochet lace and cotton eyelet ribbon compare?

- Cotton crochet lace generally involves higher labor intensity or machine time due to intricate stitching and open patterns, resulting in relatively higher per-unit costs.

- Eyelet ribbon production is more standardized and often benefits from automated embroidery, reducing labor costs and enabling competitive pricing for bulk orders.

- For high-volume OEMs, eyelet ribbons typically offer better cost efficiency.3

Is crochet lace more expensive to produce than eyelet lace?

Crochet lace production can be more labor-intensive, especially if handcrafted, leading to higher costs. Machine-made crochet lace reduces costs but may still be pricier than eyelet lace, which is often produced using automated embroidery machines.

What factors influence the cost of producing cotton lace?

Factors include the complexity of the design, production method (handmade vs. machine-made), labor costs, and the quality of the cotton used.

What stability and durability differences affect their application in garments?

- Crochet lace’s openwork and softer construction can be more delicate, requiring careful handling and suitable garment placement to avoid damage.

- Eyelet ribbons offer enhanced dimensional stability and resilience due to reinforced fabric edges and tight stitching around eyelets, making them durable in activewear and children’s garments.

- Stability considerations influence the choice depending on garment use, washing requirements, and expected wear.

Which is more durable: crochet lace or eyelet lace?

Eyelet lace, being part of the fabric with reinforced embroidered edges, tends to be more durable and stable. Crochet lace, depending on the stitch tightness and thread quality, can be more delicate and may require careful handling.

How does the durability of lace affect its use in clothing?

More durable laces like eyelet are suitable for everyday wear and items requiring frequent washing. Delicate laces like crochet are often used in garments intended for occasional use or that require gentle care.

How do raw material supply chains and risks differ for these two lace types?

- Both use cotton threads; however, sourcing crochet-quality yarns may require higher-grade fibers to ensure softness and longevity, whereas eyelet ribbon relies on consistent embroidery thread stocks and ribbon fabric suppliers.

- Eyelet ribbon supply chains tend to be more streamlined given industrial-scale embroidery capabilities, whereas crochet lace supply can be influenced by artisanal availability if handwork is involved.

Are there supply chain challenges unique to crochet lace?

Handmade crochet lace relies on skilled artisans, and any disruption in artisan availability can affect supply. Machine-made crochet lace depends on the availability of specific machinery and trained operators.

What raw materials are essential for producing eyelet lace?

High-quality cotton fabric and embroidery threads are essential. Any fluctuation in cotton prices or supply chain disruptions can impact production.

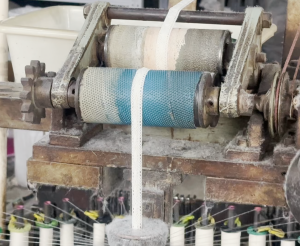

How adaptable are cotton crochet lace and eyelet ribbon to factory production workflows?

- Eyelet ribbons integrate smoothly into automated garment production lines with easy attachment via sewing or bonding methods.

- Crochet lace’s integration depends on its construction—machine-made crochet laces fit factory workflows better than hand-crocheted variants, which may require additional finishing steps.

- Large-scale OEM production favors lace types that minimize manual handling and simplify assembly.

Can crochet lace be efficiently produced in factories?

Machine-made crochet lace can be produced efficiently in factories, though the setup may require specialized machinery. Handcrafted crochet lace is less adaptable to mass production due to its labor-intensive nature.

Is eyelet lace production suitable for large-scale manufacturing?

Yes, eyelet lace is well-suited for large-scale production using automated embroidery machines, allowing for consistent quality and high output.

Which lace type is better suited for specific garment applications and large-scale OEM production?

Cotton Crochet Lace:

- Ideal for premium, decorative apparel segments where aesthetic and artisanal value are emphasized, such as bridalwear, eveningwear, or heritage fashion.

- Suitable for accent trims, overlays, or design focal points.

Cotton Eyelet Ribbon:

- Best for high-volume casual wear, children’s clothing, and functional designs needing breathable and durable trims.

- Preferred in mass-market OEM lines for ease of use, cost control, and performance.

Which lace type is better suited for specific garment applications and large-scale OEM production?

- Which lace is preferred for high-volume garment manufacturing?

Eyelet lace is preferred due to its compatibility with automated production processes, making it ideal for high-volume manufacturing.

- In what garment applications is crochet lace commonly used?

Crochet lace is often used in boutique or high-end garments where unique, handcrafted details are valued, such as in bridal wear, vintage-inspired clothing, and accessories.

For a variety of crochet lace options, you can explore Etsy’s crochet lace ribbon collection .

John Gan

John Gan specializes in professional lace and fabric customization, leading Shaoxing Yituo to expand globally with quality and innovation. He is committed to making the company a leading supplier through strong international partnerships.