Short Description:

This comprehensive guide compares cotton crochet lace and polyester water soluble lace from a B2B perspective, focusing on production costs, stability, raw material sourcing, and factory production adaptability to determine the ideal lace for large-scale garment manufacturing and wholesale.

Table of Contents

What are cotton crochet lace and polyester water soluble lace?

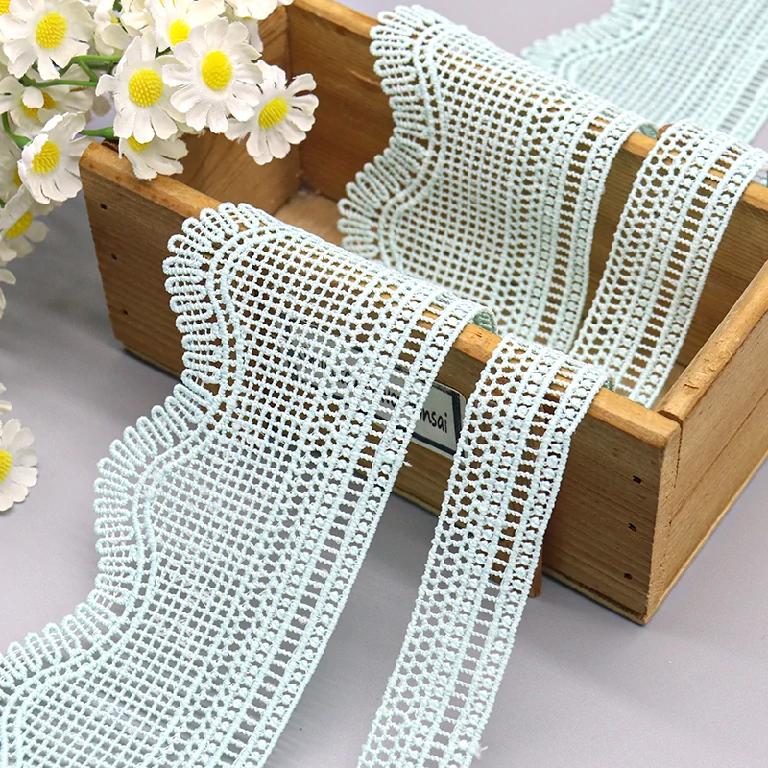

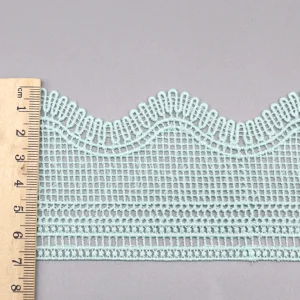

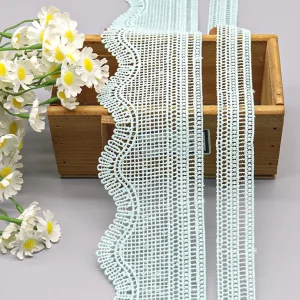

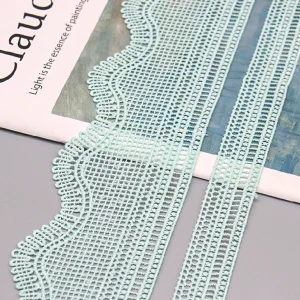

Cotton Crochet Lace:

- Crafted by interlocking cotton threads using crochet techniques, often handmade or semi-automated.

- Known for natural fiber comfort, softness, and artisanal aesthetic, favored in classic and sustainable fashion.

Polyester Water Soluble Lace:

What is the difference between cotton crochet lace and polyester water soluble lace?

- Cotton crochet lace is handcrafted using cotton threads, offering a soft and natural texture, while polyester water soluble lace is machine-made, utilizing synthetic fibers that dissolve in water to create intricate patterns.

How is water soluble lace fabric made?

How do production costs compare between the two lace types?

- Cotton crochet lace typically incurs higher labor costs due to manual or semi-handcrafted processes, along with slower production speeds.

- Polyester water soluble lace benefits from automation, faster turnaround, and less manual intervention, reducing per-unit cost at scale despite specialized materials.

- For bulk production, polyester water soluble lace usually offers better cost efficiency, while cotton crochet lace commands a premium for its handmade appeal.

How do production costs compare between the two lace types?

Is cotton crochet lace more expensive to produce than polyester water soluble lace?

- Handmade cotton crochet lace tends to be more expensive due to labor-intensive processes, whereas machine-made polyester water soluble lace benefits from more efficient production methods, reducing costs. (modaknits.com )

What factors influence the cost of producing different types of lace?

- Factors include the type of fiber used, production methods, and regional labor costs, all of which significantly impact the overall cost of lace fabric production.

Which lace provides greater stability and consistency in manufacturing?

- Polyester water soluble lace delivers consistent size, shape, and quality because of machine-controlled embroidery and standardized water soluble backing.

- Cotton crochet lace shows natural variation owing to manual crafting, which can challenge batch-to-batch uniformity in large orders.

- Stability over washing and wear favors polyester lace’s synthetic fiber properties and absence of fabric backing.

Which lace provides greater stability and consistency in manufacturing?

Is polyester water soluble lace more durable than cotton crochet lace?

How does the manufacturing process affect lace quality?

- The precision of the weaving or crocheting process and the quality of materials used are critical for ensuring consistent quality in lace production.

What are the supply chain considerations and raw material availability for both laces?

- Cotton crochet lace relies on high-quality cotton thread supply chains; susceptible to agricultural fluctuations and sometimes higher cost if sourced organically.

- Polyester lace depends on industrial polyester fiber suppliers and specialized water soluble substrates, which have well-established but niche supply chains.

- Bulk buyers should evaluate regional availability and supplier reliability for both fiber types to reduce production risk.

What are the supply chain considerations and raw material availability for both laces?

What materials are commonly used in cotton crochet and polyester water soluble laces?

Are there supply chain risks associated with lace production materials?

- Supply chain risks can include fluctuations in raw material availability, quality inconsistencies, and price volatility, affecting both cotton and synthetic lace production.

How compatible are these laces with factory production lines and automation?

- Polyester water soluble lace is highly compatible with modern embroidery machines and automated finishing processes, enabling scalable, efficient production.

- Cotton crochet lace production is less suited to full automation, requiring skilled artisans or semi-automated tools, limiting throughput and flexibility for rapid scaling.

- Factories must assess equipment investment and workforce capability when planning large orders of cotton crochet lace.

How compatible are these laces with factory production lines and automation?

Can existing machinery be used for both cotton crochet and polyester water soluble lace production?

- While some machinery can handle both types, producing cotton crochet lace often requires specialized equipment due to its handcrafted nature, whereas polyester water soluble lace is more adaptable to automated processes.

What challenges exist in automating lace production?

- Transitioning to automated lace production requires significant investment in specialized machinery and may face challenges in replicating the intricate designs achieved through traditional methods.

From a B2B standpoint, which lace is more suitable for large-scale procurement and sales?

- Polyester water soluble lace is generally better suited for high-volume garment production, offering lower costs, consistency, and seamless factory integration.

- Cotton crochet lace fits boutique, premium, or eco-conscious product lines where uniqueness and natural fiber attributes justify higher price points.

- B2B buyers should align product positioning and target segments with manufacturing capacity and cost considerations when selecting between these lace options.

From a B2B standpoint, which lace is more suitable for large-scale procurement and sales?

Is polyester water soluble lace more cost-effective for bulk purchasing?

What factors should businesses consider when choosing between cotton crochet and polyester water soluble lace for bulk procurement?

- Businesses should consider factors such as production costs, durability, environmental impact, and consumer preferences when deciding between cotton crochet and polyester water soluble lace for bulk procurement.

John Gan

John Gan specializes in professional lace and fabric customization, leading Shaoxing Yituo to expand globally with quality and innovation. He is committed to making the company a leading supplier through strong international partnerships.