Short Description:

This article compares eco-friendly cotton lace and synthetic lace, focusing on production costs, stability, raw material supply, and factory adaptability from a B2B perspective to determine which lace type is better suited for large-scale procurement and sustainable wholesale.

Table of Contents

What are the key differences between eco-friendly cotton lace and synthetic lace?

Eco-Friendly Cotton Lace:

- Made from natural, biodegradable cotton fibers often sourced from sustainable agriculture.

- Known for breathability, softness, and an organic appeal aligning with eco-conscious consumer trends.

Synthetic Lace:

What are the main differences between cotton and synthetic laces?

- Cotton laces are breathable and soft, offering comfort, while synthetic laces like polyester and nylon provide greater durability and resistance to environmental factors.

How do the properties of cotton and synthetic laces compare?

- Cotton laces are known for their natural texture and moisture absorption, whereas synthetic laces offer strength and longevity, making them suitable for various applications.

How do production costs vary between cotton lace and synthetic lace?

- Cotton lace production often incurs higher raw material costs due to organic farming and processing standards, plus the cost of maintaining sustainable certifications.

- Synthetic lace benefits from lower-cost raw materials and efficient manufacturing processes, making it more price-competitive for large orders.

- However, long-term value and brand position emphasizing sustainability can justify premiums on cotton lace.

Is cotton lace more expensive to produce than synthetic lace?

- Cotton lace production can be more costly due to the labor-intensive processes and the price of natural fibers, whereas synthetic lace benefits from more efficient manufacturing techniques.

What factors influence the cost of producing lace fabrics?

- The type of fiber used, production methods, and regional labor costs all play significant roles in determining the overall cost of lace fabric production.

Which lace offers better stability and quality consistency in mass production?

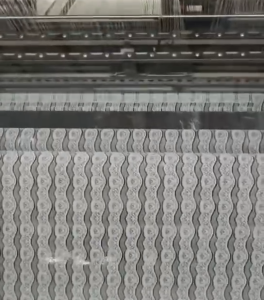

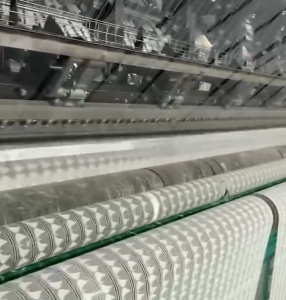

- Synthetic lace production using automated machines ensures high uniformity, consistent pattern control, and fewer defects at scale.

- Cotton lace quality depends on natural fiber variability, which may require more quality control efforts to maintain batch consistency.

- Advances in cotton processing have improved stability but synthetic lace retains an edge in manufacturing predictability.

Are synthetic laces more durable than cotton laces?

How does the manufacturing process affect lace quality?

- The precision of the weaving process and the quality of materials used are critical for ensuring consistent quality in lace production.

What are the raw material supply and sustainability considerations for cotton versus synthetic lace?

- Cotton lace sourcing involves agricultural variables, water usage concerns, and certification costs but benefits from growing sustainable cotton initiatives worldwide.

- Synthetic fibers rely on petrochemical supply chains with associated environmental footprints and regulatory challenges related to microplastics and recycling.

- Eco-friendly cotton lace appeals strongly to sustainability-focused markets, though supply stability must be managed closely.

What are the environmental impacts of cotton and synthetic lace production?

- Cotton lace production involves significant water usage and pesticide application, while synthetic lace production relies on petroleum-based materials, contributing to environmental pollution.

How do raw material sourcing challenges affect lace production?

- Fluctuations in the availability and cost of raw materials like cotton and silk can disrupt production timelines and increase costs for lace manufacturers.

How adaptable are cotton and synthetic lace production lines to factory automation and scale?

- Synthetic lace manufacturing lines are highly automated with advanced knitting and finishing machinery supporting fast, large-scale production.

- Cotton lace can be manufactured at scale but often requires additional handling steps related to fiber preparation and quality assurance.

- Factories specializing in synthetic lace may need to invest in new equipment or processes to produce high-quality cotton lace reliably.

Can lace production be automated effectively?

What challenges exist in automating lace production?

- Transitioning to automated lace production requires significant investment in specialized machinery and may face challenges in replicating the intricate designs achieved through traditional methods.

From a B2B standpoint, which lace type offers greater advantages for bulk purchasing and sustainable market growth?

- Synthetic lace offers cost-effective, scalable solutions with strong supply chain reliability, ideal for price-sensitive mainstream markets.

- Eco-friendly cotton lace aligns with growing demand for sustainability and premium natural products, appealing to brands targeting conscious consumers.

Is synthetic lace more cost-effective for bulk purchasing?

- Synthetic lace is often more cost-effective for bulk purchasing due to its lower production costs and greater durability, making it suitable for large-scale manufacturing.

What factors should businesses consider when choosing between cotton and synthetic lace for bulk procurement?

- B2B buyers should weigh market positioning, price points, and supply capabilities to select the lace type that fits their strategic goals while supporting long-term sustainability trends.

John Gan

John Gan specializes in professional lace and fabric customization, leading Shaoxing Yituo to expand globally with quality and innovation. He is committed to making the company a leading supplier through strong international partnerships.