Short Description:

A concise B2B comparison of fancy lace trim and vintage crochet lace through the lens of cost, stability, material supply, and factory-line adaptability—mapping each craft to wedding décor application scenarios so ODM teams can scale customization with predictable lead times and margins.

Table of Contents

What are the core craft differences and how do they influence bridal brand customization?

Floral crocheted lace with beads is built loop-by-loop (often cotton or blended yarns) and then embellished by hand with pearls, seed beads, or crystals, creating rich texture and artisanal depth. It excels at heritage or boho aesthetics, where tactile hierarchy and hand-finished details are a core part of the brand story.

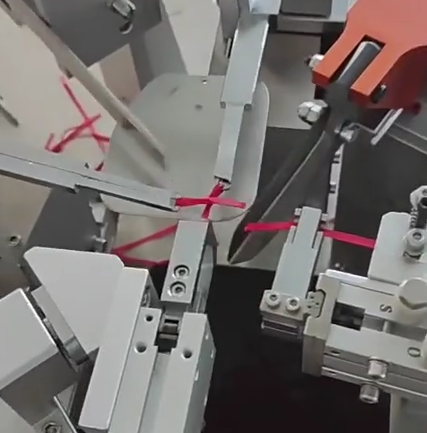

Woman garment embroidery lace trim is produced on multi-head embroidery machines over tulle/organza or water-soluble bases, allowing fast motif changes, monograms, crests, and repeatable logo elements. Digitized artwork enables consistent placement on veils, bodices, waistlines, and sleeve hems, supporting scalable brand signatures.

What factors affect the cost of custom wedding dresses?

The cost of custom wedding dresses is influenced by factors such as the quality and type of fabrics used, the complexity of embellishments, and the level of gown customization.

How do production costs compare for customized bridal programs?

Beaded crochet involves high labor minutes per meter for both crochet and bead application; costs rise with bead density, motif complexity, and width. While small MOQs are feasible, per-unit pricing remains premium, and sampling iterations are slower, pushing up development overhead.

Embroidery lace leverages automation: once a design is digitized, per-unit costs fall predictably with volume. Thread usage, stitch density, and finishing are the main drivers, and recolors or minor motif edits are low-cost. This makes embroidery trims better for tiered price ladders and multi-style brand programs.

How much does it cost to produce a wedding dress?

Manufacturing costs for wedding dresses range from $150 to over $900, depending on complexity. Simple sheath dresses are at the lower end, while heavily beaded ballgowns with custom lace appliqués are more expensive.

Wholesale Wedding Dress Manufacturers | Bulk Bridal Gown Suppliers

Which option delivers better stability and quality consistency in volume runs?

Embroidery trims offer strong batch-to-batch repeatability—machine-controlled tension and standardized QC (density, thread type, base fabric, wash tests) help maintain geometry, colorfastness, and hand feel. This predictability supports consistent visual identity across factories and seasons.

Beaded crochet has natural variance in tension and dimensions, and bead security depends on hand-stitching technique. Pre-blocking, preshrink, and bead pull tests can tighten tolerances, but achieving OEM-grade uniformity is more challenging at scale, especially under compressed bridal calendars.

How do quality control standards affect wedding dress production?

Strict quality control standards throughout production add to expenses, as each dress must meet specific criteria for craftsmanship and design execution.

How do raw material supply chains and sourcing risks affect lead times?

Beaded crochet requires crochet-grade yarns plus beads/crystals (often with metal components), amplifying BOM complexity and compliance checks (e.g., nickel-free, AZO-free dyes). Shade coordination and bead availability can extend approvals and increase MOQ exposure.

Embroidery trims rely on widely available threads (polyester/rayon), standard bases (tulle/organza), and optional accessories (sequins, small beads) with mature supply ecosystems. Dual sourcing by region, plus thread shade libraries, lowers risk and improves responsiveness for rolling PO schedules.

How do supply chain issues impact bridal gown manufacturing costs?

Supply chain disruptions have led to significant delays in material availability, forcing manufacturers to rethink logistics. Increased shipping costs and longer turnaround times contribute to overall manufacturing expenses.

Trends in Bridal Gown Manufacturing Costs: Navigating the Changing Landscape

How well do factory lines adapt for sampling, repeats, and multi-factory rollouts?

Embroidery integrates seamlessly with CAD/CAM and multi-head lines; changeovers are quick (artwork upload, thread swap), and trims sew fast with guides/folders. It scales efficiently across OEM partners, keeping takt time high and enabling synchronized launches.

Beaded crochet is better suited to artisan or specialized cells; slower feed speeds, higher inspection, and careful packing are required to prevent bead loss or snags. While ideal for hero pieces, it can bottleneck high-mix production and complicate multi-plant consistency.

What is the average time for production and sampling of wedding dresses?

Sampling requires 15-30 days after tech pack approval. Bulk production averages 45-90 days depending on order volume and embellishment complexity.

Application scenarios and B2B recommendation for customized bridal assortments

Use floral crocheted lace with beads for premium capsules—statement waistlines, heirloom-inspired veils, couture sleeves, and limited-edition gowns where handcrafted depth drives ASP and storytelling. It shines when differentiation outweighs speed and cost.

How can a bespoke bridal dress business increase profitability?

Developing a pricing strategy that reflects craftsmanship, such as offering tiered pricing and highlighting unique design techniques, can enhance profitability.

How to Increase Profits in a Bespoke Bridal Dress Business

Use embroidery lace trim as the backbone for scalable brand customization—repeatable monograms on veils, coordinated floral borders across bridesmaid ranges, and seasonal motif refreshes. For most OEM/ODM bridal programs, embroidery trims best support consistent brand identity, faster sampling, and reliable bulk execution, with beaded crochet layered in as a premium highlight.

John Gan

John Gan specializes in professional lace and fabric customization, leading Shaoxing Yituo to expand globally with quality and innovation. He is committed to making the company a leading supplier through strong international partnerships.