Short Description:

This article compares stretch crochet lace and classic cotton lace on key B2B indicators including production cost, stability, raw material supply, and factory line adaptability, guiding wholesale buyers and manufacturers to select the most suitable lace for mass procurement and efficient production.

Table of Contents

What are stretch crochet lace and classic cotton lace?

Stretch Crochet Lace:

- Combines traditional crochet technique with elastic fibers (such as spandex or elastane) to provide flexibility and stretch.

- Offers enhanced comfort and adaptability, especially suitable for fashion applications requiring mobility like lingerie and activewear.

Classic Cotton Lace:

What are the characteristics of stretch lace fabric?

- Stretch lace fabric typically contains elastic fibers like spandex or lycra, providing elasticity and durability, making it versatile for various applications.

How does crochet lace differ from other types of lace?

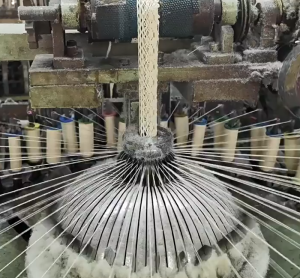

- Crochet lace is entirely handcrafted, offering unique three-dimensional patterns ranging from delicate to dense structures.

- (jdfashionfabric.com )

How do production costs compare between stretch crochet lace and classic cotton lace?

- Stretch crochet lace production often involves specialized blended yarns incorporating elastic fibers, which can increase raw material costs. The manufacturing process may require advanced machinery or hand techniques to integrate stretch elements seamlessly.

- Classic cotton lace typically uses standard cotton yarns, with established, more cost-effective production methods especially on automated crochet or lace machines.

- For high volume, classic cotton lace usually has lower unit cost, but stretch lace’s growing market demand may justify higher pricing.

What factors influence the cost of cotton lace?

- The cost of cotton lace varies based on thread quality, with heavier threads typically resulting in higher prices.

- (cottonlace.com )

Is stretch lace more cost-effective than traditional lace?

Which lace offers better stability and quality consistency in large-scale manufacturing?

- Classic cotton lace generally displays high dimensional stability due to the non-elastic nature of cotton threads and proven production techniques.

- Stretch crochet lace must balance elasticity with structural integrity, potentially introducing more variability. Producing consistent, durable stretch lace at scale requires stringent quality control and advanced equipment.

- However, improvements in yarn technology and machine settings are steadily improving stretch lace’s production consistency.

How does the manufacturing process affect the quality of stretch lace?

- The inclusion of elastic fibers in stretch lace enhances durability and consistency, making it suitable for mass production.

- (tissura.com )

What challenges are faced in maintaining quality control during cotton lace production?

- Variations in thread quality and manual production processes can lead to inconsistencies in cotton lace quality.

How do raw material supply chains and sourcing risks differ for these two lace types?

- Classic cotton lace relies on the global cotton supply chain, which is mature and well-established but vulnerable to commodity price fluctuations and crop variability.

- Stretch crochet lace depends on blended yarns combining natural and synthetic fibers, adding complexity to sourcing and potentially higher risk of supply bottlenecks for elastic components.

- B2B buyers need to consider supplier reliability for synthetic fiber blends in stretch lace production.

What are the common raw materials used in stretch lace production?

- Stretch lace is typically made from synthetic fibers like polyester and spandex, which are widely available and cost-effective.

Are there environmental concerns associated with cotton lace production?

How adaptable are stretch crochet lace and classic cotton lace to factory production lines?

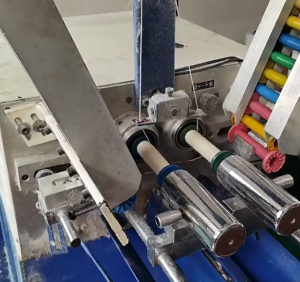

- Classic cotton lace is highly compatible with existing automated lace or crochet machines, offering streamlined mass production and reduced labor costs.

- Stretch crochet lace requires machinery capable of handling elastic fibers and maintaining stretch properties post-production, which may necessitate machinery upgrades or additional processes.

- Factories must evaluate equipment capability and process adaptability when scaling up stretch lace production.

Can stretch lace be efficiently produced on modern factory production lines?

- Stretch lace’s composition allows for efficient mass production using modern machinery, ensuring consistency and scalability.

What technologies are used in the mass production of cotton lace?

- Cotton lace production often involves traditional techniques, which may be less adaptable to modern factory automation.

From a B2B perspective, which lace is more advantageous for bulk purchasing and sales growth?

- Classic cotton lace remains a reliable, cost-effective choice favored for vast traditional markets including lingerie, bridalwear, and home textiles.

- Stretch crochet lace holds strong commercial promise in fashion-forward sectors emphasizing comfort and flexibility, such as activewear and modern intimate apparel.

- Combining both, wholesalers can diversify their portfolio and capture wider market segments, balancing innovation with classic appeal.

What are the market trends for stretch lace in bulk purchasing?

- Stretch lace’s versatility and cost-effectiveness make it a popular choice for bulk purchasing in the fashion industry.

How does cotton lace perform in large-scale B2B transactions?

John Gan

John Gan specializes in professional lace and fabric customization, leading Shaoxing Yituo to expand globally with quality and innovation. He is committed to making the company a leading supplier through strong international partnerships.