Short Description:

This guide compares black net crochet lace and colored flower chemical lace from a B2B perspective, focusing on production costs, stability, raw material supply, and factory line adaptability to determine the best choice for large-scale procurement and sales.

Table of Contents

What are black net crochet lace and colored flower chemical lace?

Black Net Crochet Lace:

Colored Flower Chemical Lace:

- Chemical lace – Wikipedia

- Machine-produced lace created by chemically dissolving fabric areas to form intricate floral motifs in vibrant colors.

- Replicable, precise patterns with smooth surfaces and bright, customizable color options.

What is chemical lace and how is it produced?

- Chemical lace, also known as Schiffli lace, is a machine-made lace created by embroidering patterns on a sacrificial fabric that is later dissolved, leaving the lace design intact.

- Chemical lace – Wikipedia

What are the characteristics of crochet lace?

- Crochet lace involves creating intricate patterns by interlocking loops of thread using a crochet hook, resulting in delicate and decorative fabric pieces.

How do production costs differ between these two lace types?

- Black net crochet lace incurs higher labor and time costs due to manual or semi-handmade processes. Production is slower with pricing reflecting craftsmanship and limited scale.

- Colored flower chemical lace benefits from automated chemical processing and mass cutting technologies, lowering labor costs and enabling faster, higher-volume production. Raw materials and dyes can be optimized for cost-efficiency.

What factors influence the cost of handmade lace?

- Handmade lace costs are affected by factors such as the complexity of the design, time required, and the skill level of the artisan.

Is machine-made lace more cost-effective than handmade lace?

- Machine-made lace offers a more affordable alternative to handmade lace, providing consistency and scalability for large-scale production.

- Handmade vs. Machine‑Made Lace: What’s the Difference? – Mehran Enterprise

Which lace offers better stability and quality control in mass production?

- Colored flower chemical lace achieves higher consistency and control thanks to mechanized and chemical techniques, minimizing defects and ensuring uniformity in large runs.

- Black net crochet lace, while valued for unique textures, shows more variability between batches due to manual methods, making quality control more challenging at scale.

How does machine-made lace ensure consistency in quality?

- Machine-made lace utilizes automated processes to maintain uniformity and quality control across large production batches.

What challenges are faced in maintaining quality control during handmade lace production?

What are the supply considerations and raw material sourcing risks for both laces?

- Raw materials for black net crochet lace (cotton or polyester threads) are generally accessible but can be limited by skilled labor availability and production capacity.

- Chemical lace relies on access to specialized fabrics, chemicals, and dyes, which may require strict regulatory compliance and supplier vetting, but the supply chain for these components is typically well-established for mass production.

What materials are commonly used in crochet lace production?

- Crochet lace is typically made from cotton or linen threads, with the choice of material affecting the final product’s texture and durability.

- Discovering Crochet Lace – The Pulled Stitch Blog

Are there environmental concerns associated with chemical lace production?

- The production of chemical lace involves processes that may have environmental impacts, particularly due to the chemicals used to dissolve the base fabric.

- The Irony of Modern Lace – Such Eternal Delight

How adaptable are black net crochet lace and colored flower chemical lace to factory production lines?

- Colored flower chemical lace aligns well with automated cutting, finishing, and sewing lines, supporting high throughput and consistent delivery for B2B demands.

- Black net crochet lace’s artisanal nature requires more manual handling, limiting factory automation and increasing lead times. Integrating it into fast-moving production lines is more complex.

Can crochet lace be efficiently produced on modern factory production lines?

- Crochet lace, traditionally handmade, faces challenges in adaptation to factory production due to its intricate and labor-intensive nature.

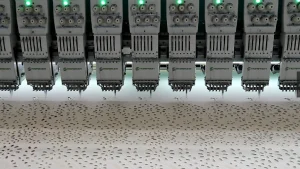

What technologies are used in the mass production of chemical lace?

- Chemical lace is produced using Schiffli machines that embroider patterns on a base fabric, which is later dissolved to leave the lace design.

Based on B2B indicators, which lace is more suitable for large-scale buying and sales?

- For businesses prioritizing scale, cost-efficiency, and consistent quality, colored flower chemical lace is typically the better choice.

- Black net crochet lace suits niche, high-end, or artisanal markets where texture and craftsmanship justify premium pricing over volume.

- B2B clients aiming for broad market penetration and faster turnover would benefit most from colored flower chemical lace’s production advantages.

What are the market trends for machine-made lace in bulk purchasing?

- Machine-made lace is favored in bulk purchasing due to its cost-effectiveness and consistency, making it suitable for large-scale production needs.

How does handmade lace perform in large-scale B2B transactions?

- Handmade lace, while offering unique designs, may face limitations in scalability and higher costs, affecting its suitability for large-scale B2B transactions.