Short Description:

A B2B comparison of floral embroidered lace trim and luxury trimming lace, evaluating production cost, stability, raw material supply, and factory-line adaptability to identify application scenarios that best drive demand for OEM dress manufacturers.

Table of Contents

What are these two trims and how do their crafts shape dress applications?

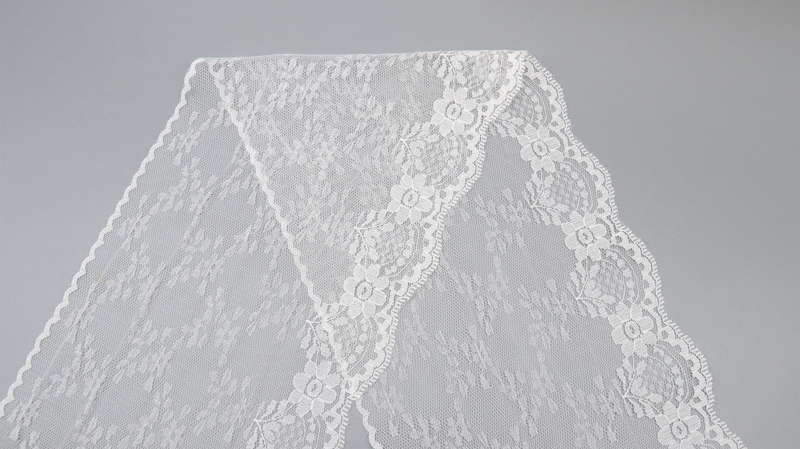

Floral embroidered lace trim is produced by multi-head embroidery on tulle, organza, mesh, or cotton bases, creating repeatable floral motifs in varied widths and colorways. The result is lightweight, versatile edging or insertion trims that integrate seamlessly into casual, occasion, and bridal dresses.

Luxury trimming lace is a premium category spanning guipure (chemical) lace, corded lace, beaded/sequined trims, and metallic-thread tapes. These deliver higher relief, shimmer, and couture-level presence, suited to eveningwear, red-carpet looks, and premium bridal segments.What are the different types of trims used in garment design?

Trims in garment design include ribbons, lace, embroidery, beads, and sequins, each adding unique aesthetic and functional elements to dresses.

The Ultimate Guide to Fabric Trims: Types, Uses, and Sourcing

How do production costs differ for OEM price tiers?

Floral embroidered trims benefit from digitized programs and machine automation; unit cost is driven by stitch density, thread count, base fabric, and finishing, with predictable economies of scale. This supports value-to-mid price ladders and fast recolors with minimal retooling.

Luxury trims carry higher costs from dense stitching, specialty materials (cording, beads, sequins, metallic yarns), and extra manual handling/QC. They fit premium price tiers and capsule ranges where higher ASPs offset slower throughput and more complex BOMs.What factors influence the cost of garment production in OEM manufacturing?

Factors such as material quality, design complexity, order volume, and labor costs significantly influence OEM garment production expenses.

A complete guide to labels and trims in the Fashion Industry

Which offers better stability and quality consistency in volume runs?

Embroidered trims on stable bases exhibit reliable width control, colorfastness, and wash performance when pre-set and tested, making repeat orders consistent across factories and seasons. SOPs on stitch density and backing removal maintain geometry at scale.

Luxury trims can match consistency but require tighter controls: guipure connectors may distort in handling, beads need secure attachment and snag testing, and metallics demand stricter crocking/anti-tarnish checks. Batch uniformity is excellent with mature programs but QC intensity is higher.How does quality control impact large-scale garment manufacturing?

Implementing stringent quality control measures ensures consistency and stability in mass garment production.

How do raw material supply chains and risks compare?

Floral embroidered trims rely on widely available polyester/rayon threads and standard bases (tulle/organza/cotton), enabling multi-region sourcing and rapid replenishment. Custom colors are supported by thread libraries, reducing lead-time risk for rolling programs.

Luxury trims depend on specialty inputs—corded yarns, sequins/beads, metallic threads, and sometimes water-soluble substrates—adding approval steps and potential MOQ pressure. Supplier consolidation and compliance (e.g., nickel-free hardware) can extend lead times for bespoke briefs.What are the challenges in sourcing materials for garment manufacturing?

Challenges include fluctuating material costs, supply chain disruptions, and ensuring sustainable sourcing practices.

How well do factory lines adapt to each trim for scalable output?

Embroidered trims are line-friendly: they cut cleanly, sew fast with folders/guides, and allow quick changeovers (swap thread/rolls), preserving takt time for multi-style OEM drops. Their flat profile reduces rework risk during bulk assembly and pressing.

Luxury trims often need slower feed speeds, added in-line inspection, and protective packing to prevent snagging, bead loss, or edge distortion. While feasible at scale, they typically reduce throughput and require more experienced operators and dedicated QA checkpoints.What is the impact of different trims on garment production scalability?

The complexity and type of trims can affect production efficiency; simpler trims may allow for more scalable output.

Application scenarios and B2B recommendation: which trim drives OEM demand?

Use floral embroidered lace trims for mainstream and fast-moving dress programs—day-to-occasion dresses, bridesmaid ranges, and seasonal color refreshes—where consistent specs, quick recolors, and competitive unit economics are essential for volume growth.

Deploy luxury trimming lace for hero SKUs in eveningwear and premium bridal capsules to lift AUR and brand perception; anchor them as statement pieces rather than line backbones. For OEM manufacturers seeking demand and repeatability, floral embroidered trims should form the core assortment, with luxury trims layered in as margin-accretive highlights.Which trims are most sought after in OEM garment manufacturing?

Functional trims like zippers and buttons are in high demand due to their essential roles in garment functionality.

What Are The 5 Frequently Used Garment Trims You Must Know About?

John Gan

John Gan specializes in professional lace and fabric customization, leading Shaoxing Yituo to expand globally with quality and innovation. He is committed to making the company a leading supplier through strong international partnerships.